Automation is changing the game for the Australian coffee industry. Service Sphere's Maurizio Marcocci explains why this movement is set to complement product consistency.

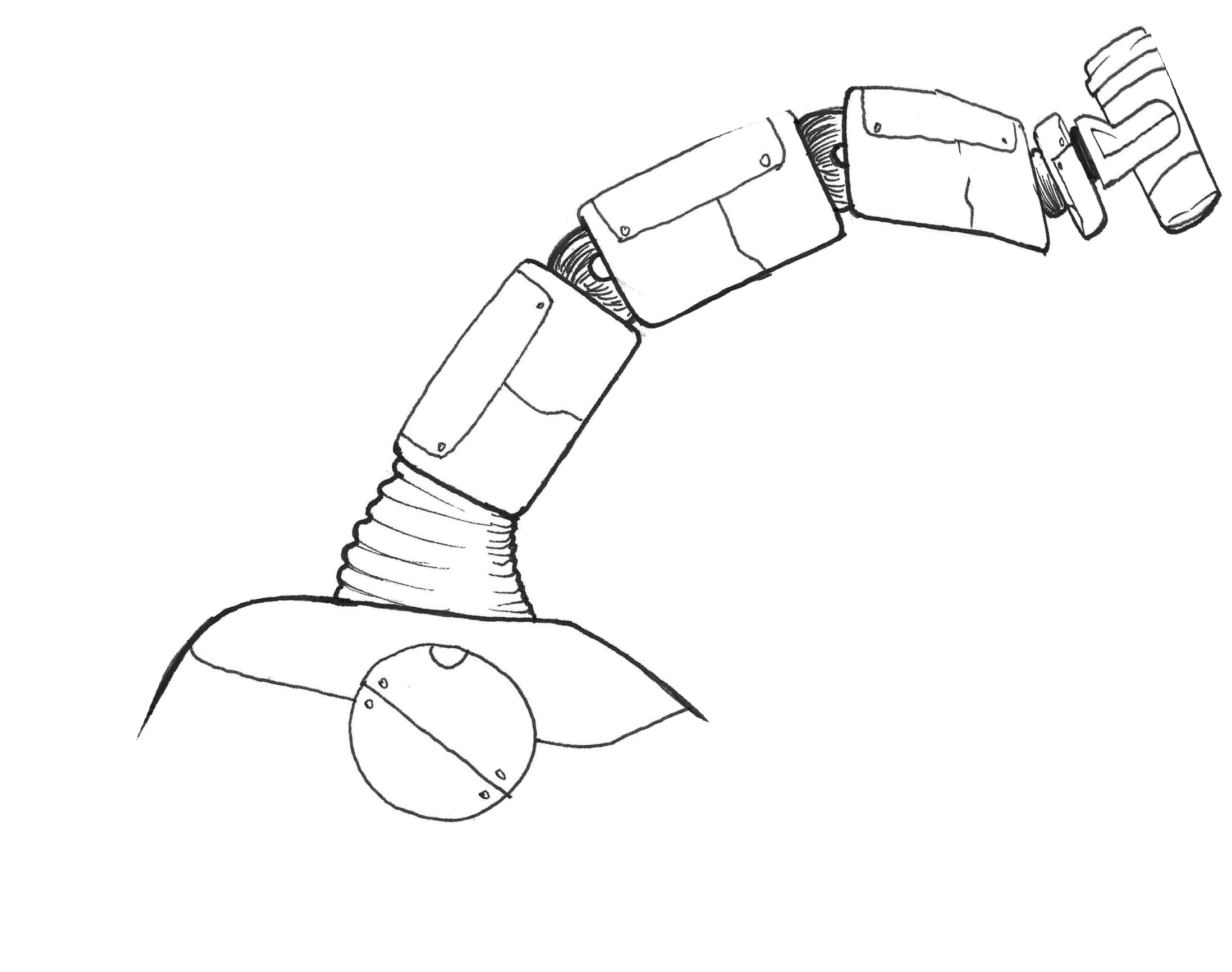

Automation is making headlines in industries around the world. In the United Kingdom, British online supermarket Ocado is testing a prototype robotic arm to assist human warehouse workers pack fresh fruit quickly. At Melbourne’s Once Alike café, a manual robotic barista called Rocky was trialled in December 2017 to serve coffee and complete all the manual gestures a human barista would repeat. In November 2017, a Chinese robot became the world’s first machine to pass a written medical exam, scoring 96 points higher than the required marks.

In the words of its creator, Liu Qingfeng, Chairman of design company iFlytek, the robot “is not meant to replace doctors. Instead, it is to promote better people-machine cooperation so as to boost efficiency”. The same could be said of baristas. Regardless of whether we believe automation is detrimental or beneficial to our craft in the coffee industry, to some extent, it’s here to stay. As much as it’s a topic of conversation at present, automation is not new. It’s just improved.

Take the Eversys E’ Barista original for instance. This superautomic range was launched in 2012 with features to withdraw the laborious and repetitive tasks of a barista, such as electronic grinder adjustment, electronic tamping, precision brewing, temperature control, and extraction optimisation. The Eversys e’foam was considered an automation breakthrough, combining steam and air for silky, microfoam-textured milk, all the while eliminating the risk of error and inconsistencies of burnt milk with its hands-off modular system.

Fast-forward six years and Eversys has put even greater emphasis into its automated technology and machine performance, as proven in the new c’2 Cameo ‘espresso machine’. With this machine, it’s not just about internal theatrics but external appearance. We tend to judge with our eyes, and in most superautomatic machines, there’s no reflection of ‘quality’ in the cup, but there is with the c’2 Cameo. It’s one machine that had visitors to the Service Sphere stand at the Melbourne International Coffee Expo scratching their heads and questioning: “is it a traditional machine or a fancy superautomatic?” It’s certainly got a place in high-end hotels, restaurants and offices, and the next step will be seeing how it fairs in a specialty shop environment, especially since baristas can change milk texture on the go, and hot water temperature.

Then there’s the La Cimbali range of Q10, S30, and S20 superautomatic machines that are versatile and easy to use. The S30 encourages innovative interaction thanks to its flexible and customisable touchscreen and interface. The S20 is the perfect solution for venues producing 300 cups a day, and the Q10 can deliver a complete beverage menu for venues in push- button or touchscreen format.

Another nod to automation is Cimbali’s Perfect Grind System on the Elective grinder. The grinder-doser is connected to the machine via Bluetooth and automatically carries out any grinding and dosing corrections to ensure optimal, constant dispensing. This device can sense a single or double shot portafilter handle, and dispense in the cradle accordingly.

When, for environmental reasons, a new coffee, machine wear or other reasons change the volume of coffee from the ideal, the machine instructs the grinder-doser to make a necessary correction in order to ensure optimal dispensing. Coffee machines aren’t the only ones making movements in automation. The PuqPress automatic coffee tamper has been an industry revelation. It’s a product that not only removes the risk of wrist injuries for baristas, but compresses ground coffee with perfect pressure and level tamp. This device is rolled out into cafés – both specialty shops and chains – throughout the country, and is widely celebrated.

Individual milk texturing devices are also running their own race in the automation department. Think Cream Creator, Übermilk, and Juggler, just to name a few. Automation may not be for everyone, but here are some of the reasons to celebrate what they bring to the industry:

• Consistency – this is extremely important for businesses with a national presence who want their product to taste the same, regardless of being in different suburbs or states. If you have a café in Melbourne and one in Queensland, you can also save identical recipes and replicate them across machines thanks to the internet. This reduces the risk of error or inaccuracies from different users.

• Control parameters – set parameters include pre-infusion, dosing, grind and milk texturing. Some machines can even pair up to the grinder and automatically program a set dosage in a specific time.

• Transparency – thanks to e’Connect and telemetry systems, users have access to transparency on key parameters of machines such as hourly, daily, and monthly productivity, technical performance and drinks profiles. Most superautomatic machines can provide key management information in real time.

• Reduced labour and staff costs – most superautomatic machines function at the push of a button with less training of baristas required. This is a plus for hotels and restaurants with less likelihood of employing a dedicated barista. They don’t have to focus on coffee as much as they do on their food because they know the coffee will be consistent, whereas each steak needs a bit of TLC to get just right.

• Serviceability – modular systems like the Eversys C’2 Cameo make life easy for technicians. When a specific module needs maintenance or replacing, techs can simply pull out and replace the old with the new. This means no downtime, loss of revenue for busy venues, or expensive call-out fees. When it comes to preventative maintenance, users can also do a vent count on a machine or will be reminded when a service is due.

• Cleaning – take the hassle of cleaning out of the barista’s hands and into that of the machine’s. Eversys models can store one month’s worth of cleaning tablets and dispense one daily through a laser-guided automatic distribution unit. This will alleviate forgetful or lazy staff and ensure the health and safety of your machine.

In the past 12 months I’ve seen a real market shift in perception of the bean to cup mentality and what’s acceptable from automation. This is largely due to improved technology that’s having a positive impact on coffee quality. Automation is making a wave in our industry, but its impact is only what we allow it to be. For the most part, it’s helping achieve what so many baristas strive for – consistent coffee quality.

Article Featured in BeanScene's April Issue. Visit the BeanScene website here.